Core Values of Enterprises

Manufacture

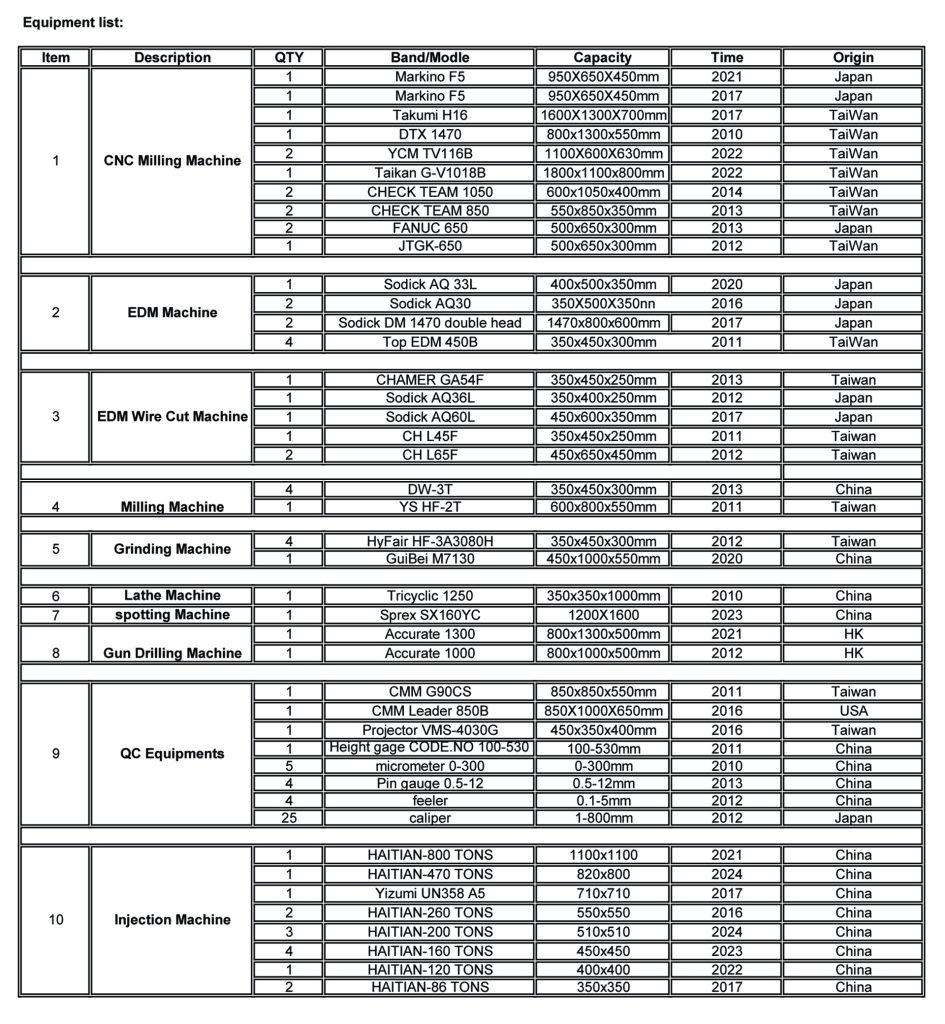

IKSONmould has 30 precision injection machine (from 90 to 800) and big injectionmachine at trial center(from 600 to2500 ton). We provide fully automatictooling to facilitate good quality and low cost. The Plastic Injection areservice by follows the ISO 9001:2000 Quality System.

IKSON has injection molding machines dedicated to mold testing. Each mold test is provided with a detailed test report (test report with pictures + full parameters + dimensional report). All molds are run for 4 hours before shipment and 8 hours for demolded molds.

IKSON Design Department is a strong strengthteam with single ENG are has excellent experience. Good design is the heartof mold, so we pays special attention to the mold construction, coolingchannels and moving mechanisms to ensure the highest quality parts aredelivered from its mold at the minimum cycle. Every mold and part design isfrom both design and manufacture experience. It is control by a consummateprocess:

1- Design meeting before mold design.(attend by design manager+designer)

2- Make design according to meeting conclusion.

3- Project meeting after finish 1th design.(attend by designmanager+designer+project ENG+ menufacture team)

4- Make 2th design and send to customer.

5- Fix the comments from customer until design approve.

IKSON Mould applies international advancedsystem – CAD/CAM/CAE in mould design.

Mostly the format of the drawing 2D in DWG orDXF, 3D in IGS, STP, X_T etc are able to communication each other.

IKSON mould is experience of mold making andinjection molding factory. We mold maker teams are precision mold experienceand mostly export mold standard. We are 90% percent molds and parts are exportto USA and Europe.

Mould standard:

We are known well DME and HASCO, Strack, FUTABA etc standard. Moulds areusing DME and HASCO components and LKM mould base.

Mould Steel:

Many kinds of mould steels are used before, such as S136, S136H and 738,718, 718H from Sweden, NAK80 from Japan and P20, 420, H13 etc.

We made many moulds with full hardened steel forall plates and inserts. We also has experience to make fast prototype molds.

IKSON Mold is an experienced mold maker and injection molding manufacturer. Our mold making team has precision mold making experience, most of the molds exported to USA and Europe meet the export standard.

Mold Standards.

We are familiar with DME, HASCO, Strack, FUTABA and other standards. Molds are made with DME and HASCO components and LKM mold base.

Mold Steels.

Many types of mold steels have been used in the past, such as S136, S136H and 738,718, 718H from Sweden, NAK80 from Japan, as well as P20, 420, H13, etc. We have made many molds with fully hardened steel.

We have made many molds with fully hardened steel plates and inserts. We also have experience in making rapid prototype molds.

IKSONmould has 30 precision injection machine (from 90 to 800) and big injectionmachine at trial center(from 600 to2500 ton). We provide fully automatictooling to facilitate good quality and low cost. The Plastic Injection areservice by follows the ISO 9001:2000 Quality System.

IKSON hasinjection machines only for mold test. Mold every test are provide detail testreports(trial reports with pic+full parameter+dim reports). All molds run 4hours and unscrew molds run 8 hours before mold ship.

Ourmolding plant has experience to using many kinds of materials in moldingprocess; we know very well every material condition and injection method. Thematerial such as:

■ PP ■PE ■ABS ■PC/ABS ■PC ■PVC

■PS ■POM ■Nylon ■PA6+(10-50) ■GF,PP+(10-30)GF ■PP+TALC

■PMMA ■PET ■HIPS ■PPS ■HDPE ■TPE ■TPR ■SAN etc.

Phone:

Address:

#29 plant, Zhicheng lndustrial , Yingguang , Li Lin Town, Zhongkai High-tech Zone, Huizhou

E-mail:

Website:

www.ikson-mould.com